Several specialized and general regulations complicate the construction and operation of a technical wastewater plant and make it anything but trivial. Planners and operators can significantly lower their expenditures by selecting an intelligent control system that supports standard and special applications equally.

One thing is for sure: It is almost impossible to determine in advance the composition of the freight in wastewater plants. Contaminations, flammable compositions or chemical reactions can occur at any time due to accidents or unauthorized discharges and this can result in outgassings, which must be classified as hazardous atmospheres. If highly flammable liquids, such as gasoline, get into the sewer system, then these float on the surface due to their lower density. As volatile materials, they evaporate fast and, depending on the concentration, they create an unhealthy or even explosive mixture. Since the vapors that are generated are often heavier than air, they inevitably collect at the lowest point of the sewer network. Therefore, the sewer network itself, as well as its structures, such as enclosed storage basins for wastewater, stowage canals, pumps or inverted siphon structures, are classified design dependent as Zone 1 or Zone 2.

Correctly classify Zones

Those subjects that apply to the sewer network also apply to the plants. They often consist of the wastewater pump station and discharge structure, which are used to guide the freight directly into the sewage treatment plant. If the structures are enclosed, then they must be classified as Zone 1. This requirement can also apply to open structures if they do not have any ventilation. Easily explosive mixtures can be generated inside, for example, due to the completely normal outgassings of the freight. This is because sludge gases are inevitably generated by feces, which are a major part of the wastewater. However, sludge gases are only slightly lighter than air and they do not not collect in the upper areas of rooms or structures, but mix with the air. The exact composition of the air-gas mixture created in this manner cannot be determined - the continuous movement of the wastewater always generates new turbulences in the air and therefore, the gas concentration within the airgas mixtures changes constantly.

A very high concentration of sludge gas generation is actually function-related in the rake structure, because the coarse and fine materials, such as tree branches, textiles and hygienic items, will be separated here. Accordingly, this area is classified in the hazard assessment as Zone 1 and adjacent areas as Zone 2. This classification also applies to the sludge water reservoir, such as shafts and structures, of the de-sludging.

The anaerobic bacterial processes that run during the sludge decomposition in the wastewater, are used in the digester tower of the sewage treatment plant for the extraction of sludge gases. These sludge gases will be converted into electricity and heat in a downstream process areas, from the sludge thickening up to the sludge decomposition, are also classified as Zone 1 and Zone 2 as part of the hazard assessment; the same applies to the outer areas of the sludge and gas container.

Constructing and automating standard conforming

Based on these challenging general conditions, adherence the relevant standards and regulations, such as ATEX or IECEx as well as the industrial safety regulation (BetrSichV), is required. This is in addition to the constructional actions f to generate an explosion protection document for the hazardous areas of their system.

This document specifically defines the explosion hazards and specifies detailed protection concepts. Germany’s DWA bulletin 217 (DWA-M 217) “Explosion protection for technical waste water plants” (July 2014) provides useful information about the practical implementation of these requirements.These relevant standards and approvals must also be used for the design of the electrical equipment of a technical waste water plant; this also applies to the equipment of switch cabinets.

Two zones - one system

The planner and the operator are normally interested in minimizing the number of components and system that must be used. For a good reason: The complex requirements that are placed by the technical wastewater plant on the control system also have an affect on the expenditures that must be anticipated by the planners and operators as part of the engineering and the future maintenance. Accordingly, they prefer products that can be used for standard applications and in special applications, such as hazardous environments, that are typical of sewage treatment plants: highly aggressive or corrosive atmospheres.

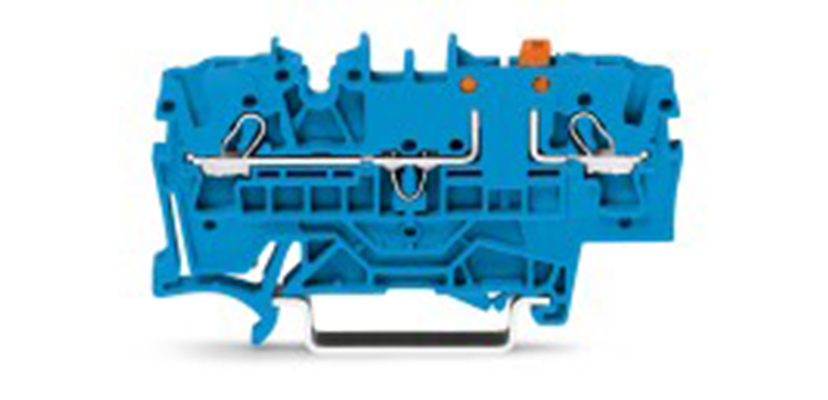

WAGO has designed its I/O-SYSTEM 750 in such a way that the same platforms are used in the ex-proof and not-ex-proof areas: Based on design details, the system is extremely versatile while still adhering to its higher ranking standard. Featuring 500 different modules, it offers the option of directly integrating different sensors in the field and transmitting very different forms of analog or digital signals bundled through TCP/IP to the control room. In addition, the WAGO-I/O-SYSTEM makes it possible to remotely record failure messages or fill levels of rain overflow basins and in doing so, control the inflow into the wastewater treatment plant in a targeted manner.

In addition to the general field bus dependency and the standard availability of open interfaces for the instrumentation, as well as the integration of entire system parts, the HART communication is also offered by WAGO. Finally, this communication compatibility also permits it to easily integrate a system expansion in the future.

Less efforts for planners and operators

WAGO’s modular design principle enables planners to equip applications in the Ex-proof and non-Ex-proof areas economically and efficiently without extensive programming. Operators can also implement special solutions, such as a partial energy measurement including the storage of all process data, with the components of an automation system. This makes it possible to establish a targeted monitoring and a management system that displays historic values. The functional benefits that WAGO’s system provides for the process engineer are completed for the programmer by offering function libraries free of charge for water and process systems.

When assessing the explosion hazard of a technical wastewater plant, then the following must be considered in addition to the typical ignition sources: electrical compensating currents or lightning protection and open flames or flying sparks. It is undoubtedly wise to let a wastewater plant’s technical system be assessed by an external expert – however, this is not mandatory. The services of external experts do not release the operator of a wastewater plant from its responsibility: The operator of the plant is in all cases liable.

Text: Kay Miller, WAGO

Photo: Fotolia.com, WAGO