Risk from flooding and hydraulic overload: To protect the sewer system – for example during heavy rainfall – the sanitary sewer and storm water are guided into so-called retention basins.

When, how much, and for how long this untreated mixed is released into the outfalls must be precisely documented by the wastewater treatment plant operators. The municipal wastewater facility for Lünen, AöR, has therefore linked their 17 pumping stations and seven structures into a comprehensive communication network. The WAGO-I/O-SYSTEM 750 is used as the central data interface.

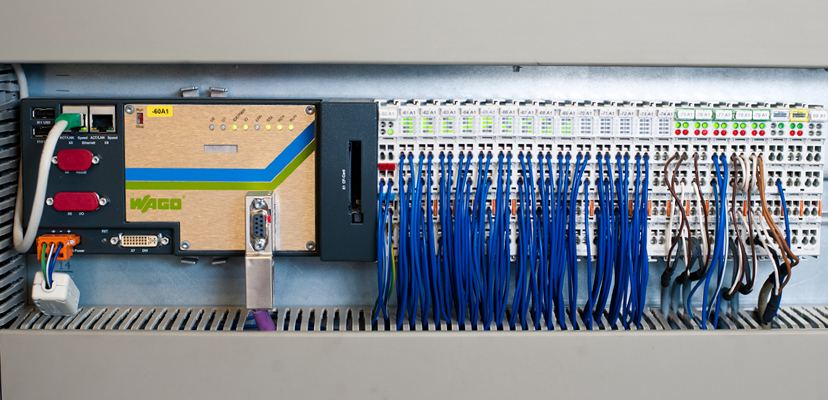

For optimum, cost-efficient, and especially safe operation, the sewer network and process technology must be both continuously and precisely monitored. Therefore, the Lünen Municipal Wastewater Facility successively brought its pumping stations up to the most modern state of automation. Dr. Bellwon GmbH from Lünen, specialists in water and wastewater facilities, were awarded the project for planning and integrating the system. The WAGO-I/O-SYSTEM 750 assumed a central function.

Monitoring in Real Time

For example, by using the PLC, which is freely programmable in the standardized languages of IEC 61131-3, the frequency converters for the pumps are controlled and the link to operators and observers on site is established on a touch panel. An additional central task for the I/O system lies in constant communication with the control center through a VPN tunnel via Ethernet TCP/IP. For Lars Laubenthal, CEO and lead project engineer at Dr. Bellwon, the networking of the pumping stations represents outstanding innovation of retrofitting work, “today, we can monitor the entire network from the control center in real time.” Dr. Bellwon GmbH was also able to consolidate all of the data logging in the server. “In this way, we increase data security because all of the logging and storing takes place centrally with corresponding redundancies via an SQL database,” he emphasizes.

Creating Clear Evidence

In practice, this server-supported documentation creates a reliable basis for controlling the wastewater facilities in an optimal operation. In addition, the numbers serve as the standardized documentation about the mixed water from the retention basins. The municipal utility in Lünen can therefore clearly prove to regulators from the state of North Rhine-Westphalia whether untreated sewage was released, wittingly or unwittingly, into rivers or streams due to technical faults or due to heavy rainfall incidents. The obligation to produce proof is detailed in Paragraph 3 of the “SüwV Kan.” The abbreviation stands for ‘self-monitoring ordinance for sewer systems’. Among others, it determines that “water level measuring devices are to be installed for continuous recorded monitoring at the most important rainfall filter beds, rain spillway basins, and storage canals in a sewer system.”

Broad Dissemination of an Industry Standard

For diverse measurement and monitoring methods, the WAGO solution offers all necessary modules from a complete system. “For the conversion, we consciously chose to use to a sustainable hardware and software that are flexible and have proven themselves in industrial applications,” states the professionally qualified engineer. The flexibility in combinatorics increases the comfort for scalably equipping individual applications and adapting them to the operator’s requirements. The WAGO-I/O-SYSTEM offers, for example, diverse interfaces, among them PROFIBUS DP or the HART protocol, in order to comfortably integrate measuring systems. Using special I/O modules, intrinsically safe circuits can be directly connected to the I/O system.

The communication redundancy presented a unique opportunity in Lünen. The WAGO-I/O-SYSTEM 750 can report data and faults in two independent ways. If the operating data layer is generated, as outlined, via the VPN tunnel to an SQL server, the WAGO technology is in a position to distribute autonomous emails through a separate exchange server. In case of an error, these then arrive directly at a smart phone in service at the Lünen Municipal Wastewater Facility. The data connection via the exchange server is then used as a backup system if network communication is down.

Reacting Correctly Faster

The Lünen example shows how facilities can be operated more effectively today using interactive solutions for remote monitoring and remote controls while simultaneously lowering costs for personnel and equipment. The use of location-independent and highly available IP technology – when paired with access via VPN technology – offers safe access to all facilities and an intuitively accessible operation using PCs, tablets, or smart phones via an Internet browser. Contrast this with many sewer systems, according to the experience of the engineers at Dr. Bellwon, in which purely collective reports are transmitted to the operators, even when an error has occurred. “This wastes valuable time until serious faults can be localized, analyzed, and remedied,” states Laubenthal.

Conclusion:

Text: Kay Miller, WAGO

Photo: WAGO