The SBB monitors the electrical systems at around 1500 locations, like train stations or tunnels, throughout Switzerland. At the end of 2012, the SBB started up a comprehensive control and error message system for this task so that they can react quickly and in a targeted fashion to interruptions or defects.

Even before the first travelers arrive, the lights go on at many Swiss train stations. This also occurs at locations where no personnel are on site. In addition to lighting, there are other systems that the SBB must control and monitor, for example, elevators, escalators, clocks, door locks, building environmental systems, and pumps. Previously, around 23 different control systems, scattered across Switzerland, accomplished these tasks. In 2005, the SBB began a project to replace these different systems with a single new one. “We wanted to reduce the complexity and thus make the costs more transparent,” explains Milun Bozovic, Product Manager for Buildings and Control Technology at the SBB. At the end of 2012, they were ready: the control and error messaging system (LSS-CH for short) at the SBB became operative across the country following a four-year long roll-out period.

High Degree of Standardization

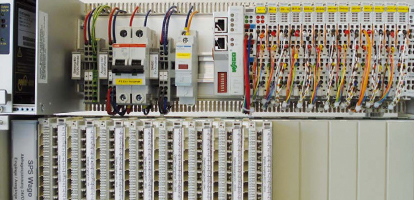

For on site data recording, the SBB equipped around 1500 locations with a programmable logic controller (PLC) from WAGO. It starts up each location in the same way: the SBB provides central controllers, each PLC commands the same software and the same references. The SBB then installed automation boxes and connected them to the control system via the SBB’s data network. Now they can convert a location in one day and bring it into operation. The locations have different dimensions. Therefore, there are two different versions of the WAGO controllers: the more data points a location has, the larger the WAGO controller. The small controller is designed for 60 data points, the large one for 200. Bozovic explains, “We install pre-finished automation boxes. However, they are very flexibly designed so that they can be supplemented with additional modules as needed.”

WAGO controllers are normally programmed using CODESYS. However, since each train station superintendent must be able to operate the controllers, the engineers installed a webserver on the WAGO controller. This enables configuration using a browser and the graphical interface. Thus, a higher degree of standardization is achieved. Milun Bozovic adds, “The train stations are all different. But they have similar systems that have to be monitored. Everywhere, there is lighting, a clock, a pump.” At the moment, there are still six 24-hour locations, from which SBB Infrastruktur monitors the entire electro-technical systems. By the beginning of 2015, there will be only four.

The software is designed for the maximum. Thus, the controllers can be configured in any way, yet they always function using the same software. The controllers can autonomously exchange data with each other across all of Switzerland. The SBB administers all nodes centrally via an engineering database, where even the graphical user interfaces for each location are stored. The integrator initially records which lighting groups, elevators, pumps, and other systems should be monitored. Then it configures the graphical user interface such that it is clear across different hierarchy levels which systems are located where.

Accurate Localization

At the moment, the LSS-CH comprises more than 250,000 data points. In order to maintain an overview at this level, a uniform designation system had to be introduced. Due to the Machinery Designation System (MDS), each machine, down to the last wire included in a controller has a unique name within the control and error messaging system. Likewise, each machine, each floor, each building, and each location has its own unique code. Therefore, it is easy to determine where a fault is located. The error messaging system is configured uniformly throughout the entire country. Each train station is designed the same way and operated identically. “The colleague working today in Zurich can work tomorrow in Lausanne,” states Milun Bozovic. An additional challenge was that every component and system must function in three languages: German, French, and Italian. This way, the employees can simply set the language for the system while the graphical elements remain unchanged.

Necessary Connection to the SBB Data Network

The SBB invested around 33 million Swiss francs in the overarching LSS-CH project to monitor electronic technological systems within the rail sector. “For us, the LSS-CH is a project that we can sell to other railway systems or even within the country,” explains Bozovic. SBB Immobilien uses it to monitor and control, for example, fire alarm systems, escalators, and elevators in the large train stations.

The system communicates exclusively over the SBB’s data communication network. Therefore, customers who want to use the LSS-CH have to have a datacom connection. Bozovic explains, “The customer receives space on our servers, but then administers their own monitoring station.” There are security considerations behind this statement. The SBB guarantees fewer than four hours of downtime per quarter at 24 hours per day usage of the data communication network. The controllers also offer a high level of security against faults: “We have already installed more than 1000 WAGO stations. The system has proven itself,” according to Bozovic.

Text: Stephan Rey, WAGO

Photo: SBB, WAGO