Providing, collecting, evaluating and using data: In addition to the PFC100 and PFC200 IoT Controllers, WAGO is expanding its digital performance portfolio with the new WAGO Cloud Data Control capability – a forward-looking method for enabling equipment and systems in a chemical facility to function more efficiently.

The trend toward digitalization has placed challenges before the chemical-pharmaceutical industry: individualized products, faster product cycles, higher levels of product diversity – all of which demands more flexibility during manufacturing at lower costs. The solution? Is not easy, but it is clever: the smart factory provides many answers to digital questions about the future.

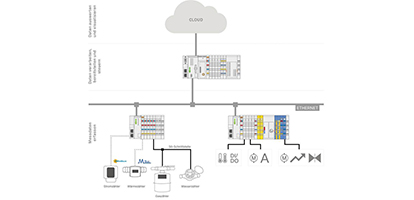

Prerequisites include transparent information about processes, performance and quality. Although a huge amount of data is being collected in industrial processes, this data is usually spread across different systems that are often incompatible. This makes it extremely difficult to network systems and processes. By using cloud communication, new opportunities for networking arise for the process industry, in particular with a view towards required system availability and the optimization of processes. In addition, manufacturing islands must be able to communicate vertically past factory walls to the cloud, so that, supervisors have access to current data across multiple production facilities as needed.

Flexible Access to Process-Relevant Data

WAGO has dealt extensively with these requirements and can offer specific approaches to solutions for system operators in the process industry. These are based on technologies that are available today and offer measurable added value to the users. WAGO Cloud Data Control, which manages and monitors all WAGO PFC Controllers as well as their applications and data, is included among the most recent approaches. A Web portal serves as a user interface for the cloud service hosted by Microsoft Azure. Customers have access to functions – like project, controller, and user management, controller status monitoring, alarm functions, and email messaging – through this gateway.

A dashboard displays texts, tables, diagrams, display elements and command buttons for seamless and intuitive operation. For customized solutions, the REST or OPC UA interface is used, for example, in energy monitoring and predictive maintenance applications. These enable users to recognize disruptions and to initiate repairs before faults lead to serious damage and cause production stoppages.

A Cloud Solution in Just a Few Steps

Both the WAGO-I/O-SYSTEM 750 and 750 XTR connect to field devices, and a PFC Controller sends data to the Cloud Data Control – the newest PFC generation is IoT-ready following a simple upgrade.By programming an IEC application with the corresponding library, the controllers can be transformed into IoT devices in just a few simple steps. Following this, status information such as Run/Stop, connection status, device information, and variables defined in the IEC program can be transmitted to the cloud and visualized.

The IoT controllers communicate with the Cloud Data Control via an encrypted MQTT protocol. The cloud connection data is configured via Web-Based Management (WBM). Libraries for CODESYS V2.3 and e!COCKPIT are also included in the scope of delivery. The variables that will be transferred to the cloud can be defined using the IEC program. This means that sensitive data does not leave the company.

Thus, the WAGO PFC100 and PFC200 Controllers form the platform that links elements from the real and digital worlds. They also offer a variety of interfaces, forming the perfect foundation for an IoT gateway. These modular and scalable controllers collect every field signal, communicate in all industrial protocols, and even enable cloud connection to sensors and actuators that themselves have no Web interface.

Secure Protection from Hackers

The ability to view process data from anywhere in the world – it sounds practical, but is it secure? Cyber security is an important topic at WAGO. WAGO’s PFC100 and PFC200 Controllers comply with the highest security standards, as they both encrypt data via onboard SSL/TLS 1.2 security protocols, and also securely transmit data to higher-level systems via VPN tunnel. They are characterized by a cross-platform real-time Linux® system, which has been available for a long time as an open-source operating system that can be scaled, updated and supports tools such as Rsync. This allows them to be used as secure gateways.

The Linux® foundation supports essential security protocols and ensures that these will be constantly refined thanks to the large Linux® community. WAGO devices therefore support IT security by design: all IT security mechanisms are integrated into the controller and cannot be disconnected by third-party access.

With M&M Software from St. Georgen as a member of the WAGO Group, the Minden-based company also has a close and integrated partner for developing industrial and technical software solutions. M&M collaborates closely with Microsoft on digital topics, like the cloud and the Internet of things, to implement corresponding solutions, primarily using Microsoft Azure. The cloud computing platform is highly scalable and provides a detailed overview of computing power, data storage, transactions, availability and security standards. It offers a quickly growing number of services and tools to provide an optimal foundation for implementing solutions tailored to specific applications for users in the process automation sector.

However, customers are also not limited to Microsoft Azure. The WAGO Controllers can transmit the data, according to desire or requirement, to other platforms, like Amazon Web Services or IBM Bluemix. Connections to third-party solutions are also feasible due to the standardized MQTT protocol.

TEXT BENJAMIN BÖHM | WAGO

PHOTO GETTYIMAGES, WAGO