WAGO, together with leading companies in the German chemical industry, applied for funding from the German government – and successfully gained it! By working together, we can make more progress in developing modular automation for process systems.

The chemical industry belongs to one of the economic sectors in Germany, whose products require energy-intensive processes, and where substantial energy savings can still be found in their production methods. In particular, the conversion from batch production to a continuous production method can potentially provide both enormous gains in efficiency and also savings in valuable time, particularly if production can take place on modular systems. These allow the easy exchange of single system modules, which promote flexible adjustments to production capacity.

Working Together toward Energy Efficiency and Accelerated Processes in the Chemical Industry

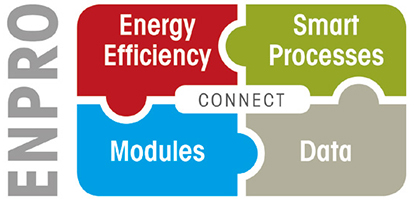

In the meantime, there are still a few hurdles to overcome; however, these challenges cannot be solved by individual companies. In the Energy Efficiency and Process Acceleration Initiative (ENPRO), major players in the German chemical industry have joined forces with representatives from system operations, module manufacturing, module automation specialists, system integration specialists, and universities. Their goal is to actively design the future of the German process industry. All participants are willing to share their expertise, in spite of market pressures to compete, because ultimately they are pursuing a much higher, mutual goal: namely ensuring the competitiveness of the German chemical industry on the global market over the long term. Toward this end, the companies are mutually developing concepts to enable the modular construction of process systems that are intelligent and flexible, which should ultimately increase the resource efficiency of the chemical processes. Because these objectives also address important strategies on the part of the German government, the ENPRO initiative is also supported by the Federal Ministry for Economic Affairs and Energy (BMWI). Explicitly, this Federal Ministry regularly determines which research and development projects will be publicly funded.

At the end of 2017, it was time: during the 3rd ENPRO meeting, diverse working groups were offered a platform to present research and development projects and to apply for funding from the BMWI. WAGO also participated in this event as a partner in the ORCA project – the efficient orchestration of modular assemblies. ORCA was one of the eight projects that applied for funding from the BMWI.

ORCA – Efficiently Orchestrating Modular Assemblies

The goals of the ORCA project are to develop methods, models, and tools for orchestrating assemblies, virtual commissioning of modular systems, and demonstrating their applicability in practice. Specifically, the ORCA project focuses on those aspects that facilitate an automated and complete commissioning of a subsystem that consists of several modules. Therefore, the project team worked on the optimal tailoring of modules, the logical integration of multiple system modules in one higher-level process control system, instrumentation requirements, and security and regulatory issues.

The partners who have joined in collaboration on the ORCA project read like a who’s who in the German chemical industry: Evonik and Merck represent system operators and module manufacturers, Samson produces field devices, X-Visual and ABB are software developers, and Siemens and WAGO design automation systems. The team is supplemented by two university partners: the Technical University of Dortmund and the Technical University of Dresden, where Leon Urbas, who introduced the ORCA project during the 3rd ENPRO meeting, is professor for process control technology.

Recommended as a Partner due to DIMA

It is no coincidence that WAGO is standing along side global players in automation technology, like Siemens and ABB, in the ORCA project. As Benjamin Böhm explains with evident pride, “Since the introduction of the DIMA concept in November 2014, WAGO has made a significant mark in modular automation in the process industry.”

WAGO is thus highly regarded as a partner in the ENPRO Initiative, which the company joined in 2017. Böhm began the ORCA project with the premise that, “The experience that we have collected for DIMA could be introduced into the collaboration prior to the competition.”

Placing their own economic interests in second place is nothing new for WAGO. In 2014, WAGO published the core of DIMA, the module type package (MTP), making it available for development within the wider community of chemical companies. “The wheels that we would have to turn in order to change the philosophy of automation in the process industry are simply too large for a company like WAGO,” explains Böhm. “On the other hand, if we can work together in a consortium, then the entire German economy can profit from this in the future.”

BMWI Invests in ORCA

This is an impression that the decision makers at BMWI obviously share, since the intentions and efforts of the ORCA project team were granted particular attention. There is also the speculation that ORCA can uncover new possibilities. Consequently, the Federal Ministry for Economic Affairs and Energy decided to invest public funds in the ORCA project after the presentation at the 3rd ENPRO meeting. ORCA is thus one of four projects to receive support from the German government in the context of ENPRO II. According to Böhm, “We are more than satisfied with the decision. Modular automation in the process industry has thus received the status that is needed in order to thoroughly develop its potential.”

TEXT BENJAMIN BÖHM | WAGO

PHOTO WAGO, DECHEMA