Filling above-level, sub-level or below bunghole – this is what you hear when experts talk about drum filling technology. Feige FILLING GmbH – headquartered in Bad Oldesloe, Germany – is an international leader of filling machines for liquid and pasty products. The manufacturer, located in the Northern German state of Schleswig-Holstein, develops Ex-proof solutions for ATEX Category 1 because their filling machines mainly operate in hazardous areas. To meet these requirements, Feige FILLING relies on the universal WAGO-I/O-SYSTEM 750 at the I/O level.

They may be green, gray, red, blue or black, but they always contain 200 liters. Internationally standardized steel drums are widely used to fill potentially hazardous liquids, such as oils and chemicals, into robust packaging. To fill these drums, Feige FILLING has developed a turnkey filling line that also includes both handling and material flow processes. “Our customers want to fill and ship their products. They do not want to worry about how the drums arrive under the fill valve or will later materialize on the shipping pallet,” says Marketing Manager Martina Thomsen. She adds that drums are just one of many packaging types that the Feige FILLING systems can accommodate. “The spectrum ranges from IBCs and drums to small containers, such as paint buckets from the hardware store.”

Safe Filling in Hazardous Areas

Given the variety of packaging, it is no surprise that the contents are incredibly diverse as well. Of course, these fluids all have properties – highly viscous, foaming, combustible or explosive – that can make the filling process extremely demanding. Therefore, Feige FILLING’s systems must meet particular challenges, including ATEX directive requirements for the construction and operation of machines and systems used in hazardous areas. About half the filling systems that leave the company are approved for Zone 1 hazardous areas because explosion protection is part of Feige FILLING’s daily business. Fittingly, Feige FILLING considers this fact when configuring a system: “We place both inputs and outputs as close as possible to the process, where the signals are created and where they are transmitted,” explains Jörn Czysch, Automation Engineer at Feige FILLING. “Our goal is avoiding unnecessary wiring.”

Integrating the I/O Level Directly into the Process

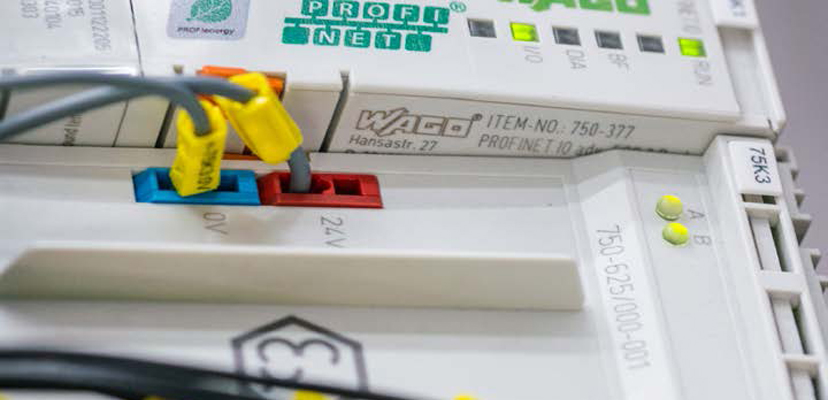

For filling process automation, Feige FILLING relies on WAGO’s intrinsically safe modules from the remote WAGO-I/O-SYSTEM 750. The modules can be installed close to the filling process for connecting sensors and light barriers on the input side, as well as solenoid and pneumatic valves on the output side. First and foremost, Feige FILLING saves both installation space and time by bringing the control system close to the process. Compared to star topology wiring, the control cabinet’s position within a production line simply matters less. This reduces engineering costs while simplifying the design of modular systems. Another clear advantage is the proximity of the control system to the process level because this relates to explosion protection: The energy stored by systems providing intrinsically safe signals in hazardous areas must always be limited. For this purpose, distributed systems are much better because shorter cable runs simply store less energy. “Cables are potential energy storage units, which is why we always keep the length of cable runs in mind,” explains Czysch, an expert at Feige FILLING.

One System, Two Application Areas

The control system of a drum filling machine is installed in a gas-tight cabinet that is slightly over-pressurized to prevent explosive gas penetration. A touch-sensitive panel is integrated into the cabinet door, allowing the system to be operated and monitored locally. All of the drum filling system’s sensors and actuators converge within the control cabinet both from the hazardous area (i.e., inside the hermetically sealed filling cabin), as well as from the non-ATEX system area (e.g., conveyors).

Feige FILLING relies on the WAGO-I/O-SYSTEM 750’s intrinsically safe modules to connect every field device located in the ex-proof area of the filling system. The system is powered by a supply module that also monitors the power supply to the downstream Ex i-proof segment. Furthermore, this module separates the intrinsically safe from the non-intrinsically safe section of the WAGO-I/OSYSTEM 750. Feige FILLING also relies on standard WAGO-I/OSYSTEM components for the machine areas that require no special explosion protection.

High Availability through Standardization The advantage:

From an engineering perspective, only one solution is used for system automation – regardless of whether the devices are connected in hazardous or non-hazardous areas. “It is extremely important that our system designs are very similar to each other,” says Axel Frank, Head of Automation Technology at Feige FILLING. “Last, but not least, maximizing our system equipment standardization helps us minimize the failure probability of individual components.”

Because the remote WAGO-I/O-SYSTEM 750 readily covers both hazardous and non-hazardous areas in one system, Feige FILLING can always equip the system automation with functional technology without leaving the stability of a standardized system.

According to Czysch, there is one more advantage to working with WAGO, “We can rely on WAGO’s willingness to innovate. WAGO kept advancing the I/O-SYSTEM 750 to provide us with new items and did not give up when additional requirements were established.” To proof this point, the Feige FILLING expert referred to WAGO’s blue, intrinsically safe modules for Ex protection and added, “They were not available when our partnership began.”

Text: Benjamin Boehm WAGO

Photo: Thorsten Sienk