With DIMA (Decentralized Intelligence for Modular Applications), WAGO has developed a concept to increase efficiency in process engineering – and it has already been tested, and proven, on land. But can this method be adapted to maritime transport? And if so, how?

Today, shipyards are essentially forced to meet delivery dates, and they must do so perfectly. Mastering complex processes and systems thus becomes an important challenge. In fact, automation and software are already determining a ship’s complexity: Terabytes of data are collected aboard ships. However, the work of shipyards and system integrators is complicated by the ubiquitous requirement to create the conditions for data collection. The shipyards must work closely with the supplier of the higher-level monitoring and control system to synchronize systems from different manufacturers during commissioning. Ultimately, this total system integrator has a key function during commissioning. The integrator is required to make changes and perform the integration test on board. Work is sometimes only possible with one job being performed right after the other, and these hours are generally more expensive than those in the workshop. For their part, shipping companies must now concentrate more than ever on their core business: The mapping of a global logistics chain. If they need data from their ships, they rely heavily on the integrator who provides the ship’s integrated monitoring and control system. Changes in subsystems, such as the bunkering system or the boiler, mean that the boiler supplier has to come aboard, for example. In addition, the integrator must also enter the additional variables or measured value ranges into the higher-level system.

The boiler supplier, as an example of any sub-system manufacturer, must be permanently involved in the extensive coordination with many monitoring and control system manufacturers to ensure a viable and standard-compliant visualization of the boiler circuits. If there is any doubt, even the regulation of subsystems will be performed at the management level.

How Can DIMA Function on a Ship?

With the complex system landscape on a ship, it makes sense to allow each member of the value-added chain to focus on their core competencies: Subsystem manufacturers construct their own systems, including automation and visualization. The system integrator and the shipyard assemble the subsystems. The ship owner handles logistics, receives greater investment protection for their ships and reduces their dependency on key suppliers. This procedure already reflects reality on the mechanical engineering side. However, in the field of electrical engineering and software components, interfaces are less standardized, yet the subsystems are very closely linked – even at the management level. They are also usually centrally automated.

By implementing the following measures, decentralized intelligence for modular applications could also be implemented on a ship:

First, a decentralized automation structure must be established in the subsystems.

Second, a software interface with a high degreeof abstraction must be described. The high degree of abstraction in this case means that the subsystem is considered a service. Services can be started, stopped and parameterized, among other things. It is technically the same for the process control system, which then becomes the process control level, regardless of whether it starts the main engine, the boilers or the air-conditioning system.

Third, information is exchanged instead of data. All of this should be performed using a uniform standard that provides vendor independence.

Increasing Complexity Requires New Solutions

To this end, WAGO has worked together with Germany’s Helmut Schmidt University in Hamburg and the Dresden University of Technology to develop the DIMA concept for process engineering.

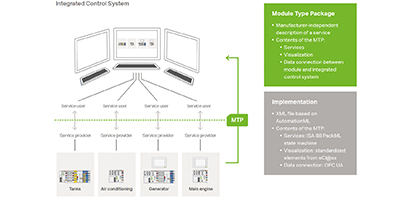

DIMA (Decentralized Intelligence for Modular Applications) covers the requirements mentioned above and currently flows into the VDI/VDE 2658 guideline and the NAMUR NE148 recommendation. At the heart of the method is the Module Type Package (MTP) for services and information. It describes the exchange of information via OPC UA. Service orientation is ensured by a state machine, which is standardized per IEC 61512. The visualization is described in the subsystem by means of AutomationML (Markup Language) and is thus functionally identical in the local control as in the machine control room or on the bridge. Only the representation follows the design of the respective manufacturer.

Tests on a pilot plant of the process engineering showed that plant commissioning is possible within 2.5 minutes. In the case of conventional commissioning, this would otherwise have taken several working days to adapt the control system. The positive experience in process engineering and the broad manufacturer support in the field of automation lead to the theory that the advantages of service-oriented software used in automation can also lead to efficiency improvements in shipbuilding.

Text: Norman Suedekum, WAGO

Photo: WAGO