While general cargo and container ships can easily count and add up the loads connected to their cargos for effective load management, precise level measuring devices are required for tankers. Krohne Marine from Norway is considered one of the global experts in this field, with more than 50 years of experience in designing load-monitoring and management systems for tankers. Krohne is using standardized control technology from WAGO in their new generation of “Cargomaster” systems, and replacing their proprietary electronics.

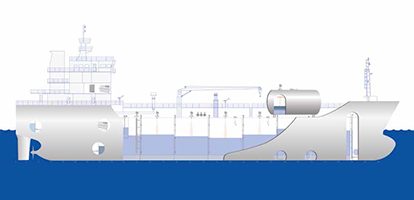

By using “Cargomaster,” ships’ crews constantly have the level of their tanks at their fingertips. The complete solution from Krohne Marine includes the entire monitoring system, from alarms, to visualization and connection to higher-level control systems, in addition to straight level measurement systems. Krohne uses their OPTIWAVE 8300 C Level Radar for the actual measurements at the load level. In addition to level measuring, the system – designed in Brevik, Norway – can also monitor pumps, conduits and the ship’s draught. Until recently, the Norwegians developed most of the necessary electronics themselves – primarily with the assumption that this would maximize precision and uptime. Their innovation is reflected in an abundance of patents, among other things.

Standardized instead of proprietary

Krohne Marine is symbolic of proprietary systems, which function excellently; however, against a background of long operating times during freight travel, they also raises costs for product updating, replacement part inventory and service. These outcomes are typical for proprietary developments, particularly in control hardware. Therefore, within the context of upgrading “Cargomaster,” Krohne went looking for a partner in industrial control technology, with whom they could perform maritime tasks with off-the-shelf products. The use of standardized components was possible because the Norwegians’ expertise lies in the design and implementation of software, rather than the hardware, as the Director of Research and Development at Krohne Marine, Svein Henriksen explains. “Using off-theshelf products currently allows us to reduce costs, primarily in development and production,” adds Henriksen.

Optimal – in terms of price, performance and uptime

Prior to making the strategic decision to rely on WAGO’s industry-proven, standardized control technology in their tank management systems, the Norwegian company compared diverse solutions from leading manufacturers. “We were looking for a supplier with products that could accommodate our requirements without long adaptation times – even in areas with extremely high demands, like explosion protection. In addition, the products that we use have to have the corresponding approvals from the classification agencies,” explains Henriksen, who manages the Service Department at Krohne. From a functional perspective, the new hardware had to provide high performance – especially in communication capabilities. These criteria ultimately led to the decision to use the WAGOI/O-SYSTEM 750. “With WAGO, we found a vendor that meets our needs,” states Jon Anders Eriksen, the man in charge of process control technology at Krohne Marine. The collaboration functioned extremely well from the start – including intensive support in software engineering and training.

Unforetold options

The partnership ultimately led to a system in which the software was not merely implemented in the new control hardware, but instead was highly adapted for optimal interplay between software and hardware. This in turn led to a significant increase in performance compared to previous generations.

By deciding to stop developing their own hardware, and to begin using standardized modules, Krohne Marine was also able to tap into advantages for applications in the Ex areas. Background: The I/O-SYSTEM 750 includes modules for Ex and non-Ex areas. Functionally, these modules are not different; they are distinguished by their design and external color. Within the WAGO system, blue is the color for explosive areas. This consistency in the product portfolio offers the Norwegians an advantage: they no longer need to consider whether a wiring installation falls under Ex-protection or not. From the perspective of the software engineers, only the functions are relevant because there are no longer any spatial restrictions. In addition, the blue I/O modules eliminate additional components because Zener barriers are no longer necessary in the control cabinet. This detail not only saves space, it also makes the installation easier, as there are fewer components to be wired. This, in turn, increases operating safety due to the lowered risk of mismating or component failure.

More time for core competencies

For Krohne Marine, these points were exactly what drove their decision to use standardized industrial technology. Due to their large series production, which includes sophisticated production monitoring routines, Krohne Marine also benefited from reduced failure rates in the components used. The spring clamping technology in the WAGO-I/O-SYSTEM also contributed to reliability, as the high vibrations aboard a ship demonstrate the system’s high performance.

Using off-the-shelf products pays off – even in the maritime sector. WAGO’s standardized control technology also functions reliably in the harsh environmental conditions at sea. “We have not had a single complaint,” emphasizes Henriksen. The cost reductions connected to the standardized products are visible in many areas at Krohne: fewer components and less inventory are needed, faster configuration and assembly, better availability of replacement parts and service around the world. “During development, we can now concentrate more on improving the functionality and user-friendliness of our systems,” concludes Henriksen. The R&D Manager sees sustainable advantages that will significantly sharpen his company’s competitive edge.

KROHNE Marine

Krohne Marine is considered one of the leading manufacturers of tank monitoring systems aboard ships. Ballast, fuel or cargo tanks: Tailored solutions from the Norwegian company are installed in all types of ships – from small tankers up to chemical barges. Krohne Marine, which is headquartered in Brevik, has completed almost 1,000 systems since the company was founded in 1957. A digital milestone in the company’s history was the 1997 development of the first level measuring system for ships that utilized electrical data.