The stability of mobile cranes on land is comparatively easy to ensure; a suitable counterweight is set based on the load, and a few minutes later, hydraulic supports extend several meters out for balance. However, it is commonplace that bulky and especially heavy loads are usually transported via water to their destinations. This raises the question as to how stability is ensured for onboard cranes – water is known as an unstable surface. Systems made of pumps, valves and ballast tanks hold cargo and commercial ships upright. Often called “heeling pumps,” these systems prevent listing of the ship’s body in the case of unevenly distributed loads. To control them, the specialists at BESI rely on PFC200 Controllers from WAGO, in combination with the I/O-SYSTEM 750 for Ex and Non-Ex areas.

Vessels which can be identified from afar are called “MPV Heavy Lifters” – as they have at least two large cranes on deck. These multi-purpose vessels are designed specifically for handling bulky and heavy cargo. According the Michael Borchers, Chief Technical Officer at BESI, their cargo has included rocket parts, turbines and even entire trains. In a current new construction project, the two cranes of one “MPV Heavy Lifter” can exceed more than 1,500 tons of lifting capacity. The heeling compensation systems on such ships have to be configured with corresponding abilities.

“The ship has compensation tanks distributed across the entire stern, which our system can quickly and precisely empty or fill with ballast water,” explains Borchers. This is the only way for the ship to maintain its balance during loading and unloading. Lifting the cargo and compensation by the pumps is performed in parallel. Consequently, the loading process can only move as fast as the heeling pumps are able to create weight compensation using ballast water – nevertheless, this should function as fast as possible to maintain short logistics times, according to Borchers.

However, the heeling compensation system must function reliably, above all, regardless of the time demands. “If one pump suddenly fails, then an entire ship can turn extremely fast,” states Borchers. By this, he means that the boat will capsize, or “turn turtle,” as it is colloquially known. “If the heeling system is interrupted, then the crane operator cannot react fast enough to lower the load at the correct time when threading heavy loads onto the deck.”

Dropping the load from the hook in an emergency is still possible from the quay, because the ship can use the quay itself as a counter weight; however, this is impossible from the sea-side, because the load would crash onto the ship.

Redundant Industry Standards

This is a scenario that explains why BESI relies on exceptionally reliable technology and equips its systems with sufficient redundancies. To control the “flow management” process, the company from Bremen uses WAGO PFC200 controllers – and in a redundant and spatially distributed function network configuration. BESI groups the heeling system, as well as the measurement, control and monitoring of tank contents under flow management. Due to the high fuel consumption in large commercial and container ships, fuel and ballast water must be regularly transferred during travel so that the ship retains a stable trim that’s optimized for energy efficiency. When ships are in a harbor, the heeling systems can engage automatically on the basis of tilt sensors; at sea, the weight compensation between fuel and ballast water is executed manually. “No automation system is able to compensate for wave amplitudes 100 % of the time,” explains Borchers, “because they constantly change and are unpredictable.” Automatic operation of an electronic heeling compensation system is therefore forbidden while at sea. This is why cruise ships mechanically stabilize the body of the ship during heavy seas by extending stabilizing fins, which provide more inertia based on their resistance.

One System Also Includes the Ex Areas

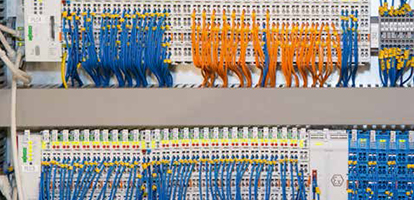

Tanks, pipelines, pumps, valve fittings: the flow management components from BESI penetrate cargo and commercial ships like a main artery running from stem to stern. Due to this fine-grained distribution, subsystems may also be installed in areas which fall under explosion protection, so BESI must use intrinsically safe components with Ex-i approvals in their automation. “Areas are classified depending on what is in the vicinity of the wiring installation, for example, fuel tanks,” explains Borchers. Within the I/O-SYSTEM 750, WAGO offers a special variant that is visually distinguished from standard modules thanks to its blue housing. And while these blue Ex-i modules are designed for use in potentially explosive areas, their functionality matches that of the standard modules. This means that there is no difference in their programming. “We can program the control technology in both the Ex and Non-Ex areas with the software environment that we prefer, without having to establish complex links between different systems,” according to Borchers. This means that BESI’s engineers do not have to set up secondary or tertiary systems, and can consistently program all modules in one pass – and they can use the standardized languages from IEC 611313 (CODESYS) to do it. The advantage of this consistency for BESI is that the software engineers do not have to consider whether components of the heeling system are installed in a hazardous or non-hazardous area. Borchers emphasizes that, “We can use one system to operate in both areas, and that system is identical in function and programming, which makes our lives significantly easier.” This is in addition to the fact that the WAGO components that are important for BESI have relevant international approvals for maritime use.

Extra Space by Omitting Zener Barriers

The consistency of the WAGO I/O-SYSTEM 750 also saves time during wiring. Because the intrinsically safe sensors, like level gauges, or the actuators, such as valve relays, can connect directly from hazardous regions to the blue I/O modules, isolation amplifiers – which would otherwise be required – can be omitted. Isolation amplifiers are used in hazardous areas to limit the energy in the electrical circuit, essentially preventing ignition of the explosive atmosphere. Since BESI can omit the Zener barriers, there are not only fewer components in the switch cabinets, they also require less of the valuable onboard space. The Chief Technical Officer contrasts WAGO automation to a less elegant solution, “If we were to connect, for example, 50 devices from the Ex area to the I/O level, then I would need almost one entire control cabinet just for the isolation amplifiers.” Sufficient space is, however, never available – even in new construction – at least for technical equipment. Borchers understands that, even though the level of automation is increasing, space is only grudgingly provided for it. Ultimately, ship designs are optimized to devote as much free space as possible for cargo. “That is why compact automation systems with high degrees of integration are so important.”

Text: Joerg Schomacker, WAGO

Photo: WAGO