With the opening of the “Cisco openBerlin Innovation Center,” the global leader in Internet and network solutions is writing a new chapter in building technology. In less than one year, a factory located on the EUREF Campus in Schöneberg Berlin has been transformed into a Lifestyle Workspace, which provides Cisco with an idea factory and innovation platform for the “Internet of Things” (IoT) in order to search for more of the same. Implementing the project required partners invested in innovation. These include HOSCH Gebäudeautomation in cooperation with WAGO; the IoT specialist, relayr; and many other start-up companies.

At first glance, the Cisco Innovation Center building captivates with its charm. Built in the early 20th century, the vintage industrial brick building appears warm and inviting, providing an impression linked more closely to a start-up than a global IT corporation. Which is part of the strategy. “Our focus was not on the building technology as such, but instead, we asked ourselves about the people who work here, what they need to feel comfortable and to give their creativity free rein,” explains Mitko Vasilev, cofounder and CTO of openBerlin.

IoT forms the center of openBerlin, which focuses on manufacturing, transportation, and logistics. The project gains Cisco an open platform for partners, start-ups, and other enterprises, in order to globally accelerate development. For this reason, the idea factory was conceived as an open structure and equipped with about 100 workstations. Cisco wants to draw in researchers, developers, and representatives from leading institutions, customers, and partner firms, like azeti, Bosch, and Intel, in order to collaboratively work on innovative IoT solutions.

BACnet/IP Backbone

The former manufactory is located near the Berlin Gasometer, and production continued there up until 2014, which made its transition to the idea factory an ambitious project with respect to time. In order to create a display piece for the “Internet of things,” Cisco also set the technological bar extremely high. This included equipping the space, around 1,000 m2, with more than 10,000 sensors and high-tech communication units to detect the most detailed information about current conditions as well as movements and locations of people within the building. The data collection extends from lighting and climate conditions through facial recognition up to smartwatches.

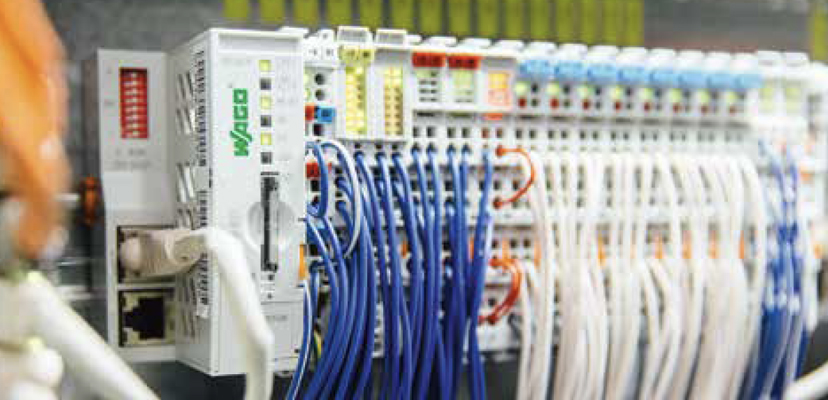

When selecting the technologies for the building, open source standards and communication ability were ranked most important. In terms of cooperation, Vasilev emphasizes that, “We needed partners who believe in our vision, are open to new concepts, and bring with them the flexibility to implement this under time pressure in order to successfully realize this project.” The team was granted only three months to design and install the building automation. For the IP-based aspects, Cisco turned to relayr, Berlin-based IoT experts. The system integration specialists, HOSCH Gebäudeautomation from Teltow, and their technology partner, WAGO from Minden, provided the designs and implemented the building technology. WAGO’s 750-831 BACnet/IP Programmable Fieldbus Controller with CODESYS forms the core of the system. As the link between the IP-based sensors and the conventional building technology, it takes on the control of room automation and lighting technology.

Building Management Systems Become Obsolete

The finely modular design of the BACnet Controller, part of the WAGO-I/OSYSTEM 750, offers an extremely high level of flexibility in the compilation of the necessary I/O modules, and thus a high degree of scaleability. In addition, technology islands using different protocols, like LON®, KNX, MP-Bus, EnOcean, and SMI, can be easily united into one system. For example, the meters in openBerlin tap electrical consumption and hot water using M-Bus, and the lights are controlled via DALI. In addition, the BACnet Controller takes on the control of all pumps and fans for room temperature regulation.

WAGO’s controller communicates with an IoTbased control system using BACnet. There is no building management system. The building’s multifunctional sensors, around 3,000 of which have since been installed, and which unite eight sensors in one device, transmit their data via wifi and Bluetooth®. The data are then collected, filtered in a fog gateway (micro cloud) stationed in the building, and provided for use via a Web application with access to the cloud. Users can use any smartphone or tablet to individually regulate light scenarios, among other things, at their individual workstations, with continuous light intensity settings and color options.

Data Pool of Inexhaustible Possibilities In principle, however, the building automation is designed to automatically set lighting and the indoor climate control to the optimal comfort conditions for employees, customers, and partners, without outside intervention. This means that light intensity and color change according to the season or time of day, so that the best conditions prevail for the individual person, or in harmony with the use of the room or workstation. For optimum indoor climate conditions, the sensors detect temperature, humidity, and CO2 content, which the BACnet Controller then processes. For example, if more people gather in one space, the system registers this and automatically lowers the room temperature.

“At the moment, we record 26.5 GB of data per day,” states Vasilev. “Of that, we probably use only about 5%.” This should change in the future as the system is expanded by artificial intelligence in order to integrate, for example, proactive measures in building automation. This project is impressive, not just due to the level of innovation, but also with regard to the investment costs and energy efficiency. In comparison with other Cisco properties, the initial investment saved around 30%, while the energy savings amount to around 60%, due in part to the need-based temperature and lighting control.

Vasilev provides a positive summary, “We are highly satisfied with the results of the project. The IoT-based building automation, which we developed with our partners, is the most innovative and modern open-source system. At the same time, it relies on components that are available in series production.” The concept additionally serves as a global model for other innovation centers and Cisco projects. Due to high system flexibility, Cisco was able to achieve investment security and create the ideal basis on which to realize many other ideas on site.

TEXT STEPHAN LAMPE | WAGO PHOTO KLAUS HEYMACH | vor-ortfoto. de