They reminisce fondly about the early days, when they brought their first X-ray inspection systems to the market. “At the time, we hardly knew what ppm meant,” R&D manager Martin Sokolowski says with a wink. Today, the engineers at Nordson MatriX focus on improving resolution at higher cycle speeds, while simultaneously creating their machines in record time, even though none are identical. WAGO automation modules have always supported a high degree of customization, and lately – the e!COCKPIT engineering software is the latest contribution to the cause.

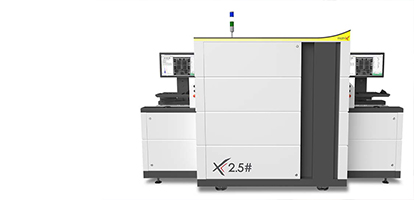

Greater accuracy, speed and flexibility: Manufacturers of high-value and safety-related products place stringent requirements on their X-ray inspection systems. Nordson MatriX meets these by employing a modular concept that extends from the mechanical system up to control programming. MatriX systems are used during quality control of electronic components, medical implants, and cast components. The roster of customers ranges from well-known firms in the automotive and medical industries to famous names in the consumer electronics industry.

Since 1998, the manufacturer, headquartered in Feldkirchen, has made automated machines with around 100 employees worldwide. WAGO technology played a role from the beginning. Initially, the engineers were merely interested in an I/O system that could be connected via ETHERNET. They hit pay dirt with WAGO; however, shortly thereafter, the team decided that they needed a completely new fieldbus controller. At first, the controllers were used purely as remote I/Os, without a PLC program. However, the developers were already aware that they would not be able to realize the future real-time requirements placed on control tasks using a PC application and a TCP/IP-based remote I/O.

Therefore, the controller functionality was also used and increased in the following years. Each new generation of WAGO controllers brought the increased performance necessary for greater machine development. At the time, MatriX was still named Macrotron Process Technologies; it already viewed the automation of its X-ray systems as one of its core competencies. Under the name MatriX Technologies, the company really took off in 2004 and demonstrated convincing growth rates. MatriX has been a part of the Nordson Group since 2015.

The company’s automation experts are in high demand. Programming controllers, generating circuit diagrams, providing integrated automation that keeps up with the ever-increasing miniaturization of electronics, and addressing other customer needs – their work ensures the company’s competitiveness. Purchasers naturally expect that the machines will support extremely short cycle times to ensure quality and operate at a high resolution. They also plan on receiving the Automated Inline X-ray Inspection systems (AXII), as well as any other MatriX equipment for non-destructive testing, shortly after ordering them.

Modular for fast development times

Such short delivery times for special-purpose machines place high demands on the machine concept and configuration. Christoph Bestle, who has been responsible for programming electrical systems, creating circuit diagrams, and PLC programming at MatriX since 2009, uses the WAGO-I/O-PRO development environment for control systems, based on CODESYS 2, to program the WAGO-I/O SYSTEM 750. Using this system, it was easy for him to manage the high levels of configuration effort that are required for new application fields, such as the final assembly tests on packaged, high-value consumer products, like smartphones, or for medical devices. He views WAGO’s I/O components and stepper controllers as modules to be combined as needed for automation within the framework of a modular machine in a way that is similar to how he views Pilz safety components.

The engineers at MatriX repeatedly conclude that WAGO is a partner with a comprehensive product portfolio, which they can always utilize successfully. Martin Sokolowski, Manager of R&D and Engineering at MatriX, believes this is due to WAGO’s focus on the numerous medium-sized machine manufacturers in Germany. He opines that, “WAGO also deals with orders in small quantities, thus supporting our development and growth.” Personal contact with his suppliers over many years is as important to him as that with the MatriX customers.

The IEC 61131-compliant programming system provides the system manufacturer with a great advantage in the form of integrated visualization. Christoph Bestle explains, “We install the engineering tool on every machine. This makes us flexible when small adjustments are needed on location.”

Due to the targeted integration of the latest WAGO controller generation, which MatriX has been consistently implementing for years, the developers are simultaneously able to pave the way for use of the new engineering software. One of WAGO’s next-generation PFCs, the PFC200, is the migration product for the change from the CODESYS 2-based WAGO-I/O-PRO to the new e!COCKPIT system, which is based on CODESYS 3. The PFC200 supports both software generations. The lack of complex changes in the hardware configuration or parts lists makes the transition to e!COCKPIT particularly easy.

e!COCKPIT – convenience for programmers and end users

The important development step, which WAGO completed by transitioning to the CODESYS 3-based tool, directly benefits MatriX. “Much more state-of-the-art,” Bestle calls the new e!COCKPIT configuration tool, “especially compared to the old configuration tool” The lockand-feel alone of the all-new WAGO development environment convinced him the first time he laid eyes on it. The software, which supports not only hardware configuration and programming, but also simulation, visualization, and commissioning, is based on CODESYS 3.

Bestle commends the integrated visualization, “It makes it easier for our technicians, and especially our end customers, to perform diagnostics and troubleshooting, especially when it comes to interface problems.” Of course, he also benefits from the integrated tool, whose configuration can be accessed directly from the PLC program.

He has already successfully realized his first major project with e!COCKPIT. “I really enjoyed the convenience during configuration, such as input assistance while programming,” he says. This resulted in a computer tomography inspection machine that can be used to examine batteries for consumer products.

The engineering software provides support at many points so that developers can cope with complex projects in record time. The network view allows classic network protocols, such as MODBUS, to be configured and programmed easily. Thanks to drag-and-drop and copyand-paste functions, this can be done intuitively. Due to the ability to create applications, Nordson Matrix will continue to benefit in the future from the high reusability of software modules. In this way, the proven modular concept of the mechanical engineer is further supported.

Little training is necessary for e!COCKPIT – especially for those who, like Bestle, already have experience with IEC 61131. They will quickly feel at home in the CODESYS 3-based software. The predefined libraries and the design of the user interface, with a clear menu ribbon, provide convenience and speed. Only the functions that are relevant to the task at hand move to the foreground, which increases comprehension and saves time.

Opportunities for early adopters to exert developmental influence

Bestle believes there is still room for improvement. A revision of the licensing model would be desirable in order to maintain the proven flexibility in the field. That would remove any obstacles during the generational changes to the development environment.

MatriX R&D Manager Sokolowski is also happy to be among the early adopters. “We are ready to take this step as soon as possible. The service life of our products in the field is six to ten years. The sooner that we can employ the improved engineering software, the longer we can provide support.” For Sokolowski, it is very important to up to date in the use of the latest technologies, as he understands that this can sometimes require an effort. “In this early phase of e!COCKPIT, we can play an especially intense role, thus setting standards and trends.”

Sokolowski had an immediate suggestion, stating that “We have not found a perfect solution for the issue of version control.” Archiving different versions of a project, being able to roll back to earlier versions – this has been a common practice for a long time in software development. Sokolowski would also like something similar for quality assurance in e!COCKPIT, as a plug-in for example. He emphasizes, “This could also significantly reduce effort in the field. Once versioning works this easily, that is, when it is no longer discipline based, it is guaranteed to work.” Together with Bestle, he continues to focus on the successful long-term partnership, in which WAGO expands its product range with MatriX in mind. There is no doubt that WAGO will handle this request with the highest priority and implement it as soon as possible. After all, the automation specialist listens very closely to early adopters.

Text: Juergen Pfeifer and Christian Muehlegger, WAGO

Photo: Stephan Goerlich, Vor-ort-foto.de, Nordson Matrix