The digital transition requires increased networking between different components, machines, production facilities, and even companies. Gradually, manufacturers are equipping their machines to exchange information. Yet many machines that are currently used in the processing industry still function as closed units. At most, the machines have access to sensors for detecting temperatures, setpoints, and cycle times. However, they do not have the ability to forward these valuable data. Thus, digitalization could already end at the machine level.

Which conflicts with the basic concepts of Industry 4.0. In quick summation: Industry 4.0 refers to the collection and use of data to make processes more efficient, to produce with maximum efficiency, and to leverage these to create competitive advantages. This means that Industry 4.0 can only function if all of the relevant information is available at the right time. The ability to monitor, adjust, and control every aspect of a manufacturing area in realtime thus becomes increasingly important. Machines must be able to communicate among themselves and with higher level systems. For this reason, approaches that strive for a common communication standard are becoming more common.

The History of the Common Machine Language

Although the vision of a uniform machine language sounds easy and logical, there have been only a few conventional approaches to a solution. However, they are often difficult and expensive to implement. For example, if a machine already has a modern controller, the software can be modified so that important data can be sent over a network. However, the controller software must still be programmed by software professionals, which sounds expensive and time-consuming – because it is.

Another approach is to fit each machine with a individually-designed application to monitor it. However, if multiple machines are present in a manufacturing area, and a specific application is required for each individual machine, then developing all of them can be extremely labor intensive. In addition, each application would require individual maintenance and documentation. Is there an easier solution for detecting and processing data for different machine types in order to implement the concepts of Industry 4.0 - A universal, standardized machine language?

Solutions on the Market

One single machine language has never actually existed. In Germany and Europe, companies often rely on OPC UA as the conventional M2M communication protocol in industrial production for those cases where it is important to detect data from different machine types and to convert the data to information. In North America, another, very interesting standard has been used for a good ten years: MTConnect. The groundwork for the project was laid in 2006 at the annual meeting of the Association for Manufacturing Technology (AMT is the US organization comparable to the German VDMA). At that time, the basic problem in industrial production remained that there was no uniform language between tool machines and the other systems in the production line. The first standard for recording all machine data to a superordinate company level was created in 2008, MTConnect 1.0. The “MTConnect Institute” was founded the following year, which was dedicated to the development of the standard language.

Detecting, Translating, and Displaying with Few Expenses

Monitoring machines can uncover and report a number of problems before expensive failures occur. Monitoring provides specific numbers about the cycle times, and also supports planning and logistics. This is where MTConnect comes in: by allowing companies to visualize work flows in manufacturing areas, which further enables them to optimize processes, uncover savings potentials, and take necessary actions based on the information they obtain.

The open-source, royalty free standard leverages proven internet protocols to transform data from manufacturing equipment into a standardized format. In principle, the data obtained from the machines is provided to an application, which in turn translates the data into legible metrics, which ultimately enable remote monitoring of the machine’s status and activity.

The MTConnect Standard consists of three components: an adapter, an agent, and an application. The adapter records machine data, standardizes it, and transfers it to the agent. The agent follows a prescribed XML method that organizes the data in a standard format, no matter what type of machine is being monitored. The agent buffers the data and then forwards it to the application on request. The application subsequently stores the data in a database and can display it in a way humans can understand. Theoretically, the adapter and agent can also be operated separately from one another in an ‘agent only’ solution. Diagrams or tables are used to present the output data from the machines in a way that is easier for the users to understand.

Digital Interface for Seamless Communication

MTConnect can thus be viewed as a universal, digital interface. Because it is based on a simple ETHERNET standard, it can be easily integrated into existing machines without interrupting the manufacturing process. This solution provides a license-free, open-source standard, which records data information that it can, in turn, forward to an analysis software. MTConnect can be integrated in factories as an interface and connects the data collector to the application, connects this in turn to an HTML website, and subsequently displays the efficiency of this facility in comparison to others. By using this simple concept, companies with complex machines and processes can easily digitize their manufacturing environment.

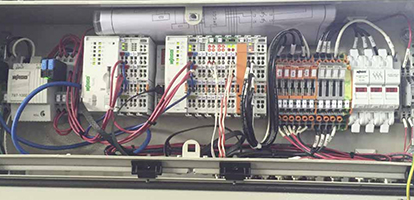

WAGO PFC100 Controllers Now Include MTConnect

Many machines are not designed for a direct connection to MTConnect adapters and agents. Therefore, WAGO has developed a digital interface for its PFC100 controller that enables a seamless transformation into a digital manufacturing area. This comprehensive digital interface commands an industrial PFC100 input system, in which MTConnect adapters and agents are already integrated. Physically, it appears in the form of an SD card, which is simply inserted into the slot provided for it on the PFC100. No programming is required. Machine data, like signal columns, energy consumption, motor speeds, or the like, can be called up easily. The inputs are con-figured via the web browser and are analyzed in real time. A software application, which can convert the data into comprehensible diagrams or tables, is the sole additional requirement. Based on the visualized data, companies can monitor, track, and evaluate the total efficiency of their manufacturing area, and ultimately improve their economic results. MTConnect is purely a read-only standard. This means that information is collected and transported to a control level where it is evaluated. However, the control level does not send any information to individual machines. Unlike OPC-UA, MTConnect does not satisfy any defined IT security regulations. This offers both advantages and also negative aspects. However, by using the PFC100 controller, the gaps can be easily and securely closed, because the controller already encrypts all data from the production area and transports it to the control level via a secure OpenVPN or IPsec connection.

Thus, the MTConnect Standard and a digital interface for the WAGO PFC100 provide an interesting solution for companies that are active in the North American market. WAGO currently supports the MTConnect Standard 1.3.

Text: Benjamin Boehm and Julia Groebe, WAGO

Photo: WAGO