To assure the power supply of Volkswagen’s Wolfsburg location, between 2005 and 2015, VW Kraftwerk GmbH will be modernizing the 110kV, 20kV, and 6kV power networks. During this process, the switching systems will be replaced one after another. With the replacement of the systems came the decision to use maintenance-free spring terminals in the future rather than screw terminals.

VW Kraftwerk GmbH is a 100% subsidiary of Volkswagen AG. It is a service provider for the Volkswagen group, as well as for communities, industry, and commerce in the areas of power supply, trading, power plant planning, and facility management.

The north/south and west heating plants operated by Volkswagen AG in its Wolfsburg location supply both the headquarters of Volkswagen AG as well as the Wolfsburg plant with power and heat. They also supply the city of Wolfsburg with heat. Some of VW Kraftwerk’s equipment was much more than 45 years old. For the modernization, the company focused on ensuring that the replacement and modernization are also associated with a cost advantage and with making a contribution to environmental protection in the interest of sustainability. The modernization of the power network is currently the largest restructuring of switching systems in Germany. By the end of 2015, VW Kraftwerk GmbH will have replaced a total of 23 switching systems. After completing all the work, 90% of the electrical connections will have been converted to maintenance-free spring terminals.

Spring Terminals Win over Planners

The first project began in 2005 with the rebuilding of a 6.3kV in-house switching system at the power plant. Criteria such as technical safety, but also return on investment played a large role in the selection of the new terminals. WAGO’s disconnect terminals are constructed so that there can be no improper operation by the user. Every conductor makes contact via its own clamping point. Furthermore, they are touch-proof, easy to handle, and maintenance-free. Aside from systemdictated contact terminals, only terminals from WAGO were used for this project.

A Remodeling of Superlatives

With the remodeling of the switching systems, the structure of the electrical supply network also changed. The new switching systems provide the required power to 6.3kV, 20kV, and 110kV networks. The terminals installed in the systems connect to both converters and control systems. “We had experienced problems with screw terminals and we were seeking alternatives. Rail-mounted terminal blocks with spring pressure connection technology in the appropriate variety were only available from WAGO at that time,” recalls Friedhelm Wolf, who is responsible for power networks and network control technology at VW Kraftwerk GmbH. Each switching system is built in close proximity to the old system. The conversion was then done during operation, during a time when the load was light. Most of the systems have already been converted.

Many Types of Rail-Mounted Terminal Blocks

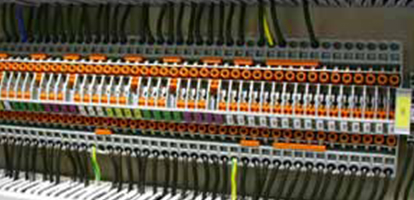

The department was especially interested in the measurement and disconnect terminal blocks in the 280 and 282 Series. The disconnect terminals of the 282 Series make contact regardless of the user, which prevents misuse. “Accurate handling is very important to us, especially in work not occurring daily on current transformer terminals, confirms F. Wolf. In order to create the desired electrical connection to the adjacent terminals, for example, for shorting current transformers, only a switch lever must be shifted manually. Integrated insulated test sockets also facilitate the direct connection of a measuring device.

For through connections, rail-mounted terminal blocks from the TOPJOB®S line as well as high-voltage rail-mounted terminal blocks from the 285 Series are used. With TOPJOB®S rail-mounted terminal blocks, the conductors make contact via the compact CAGE CLAMP®S connection, where the single-stranded and fine-stranded conductors with ferruled ends can be plugged directly. The terminal cross-sections range from 0.25mm2 to 16mm2. For the larger cross-sections, the department and the supplier selected the high-current through terminals in the 285 Series. They accommodate wire sizes from 6mm2 to 95mm2. For the terminals with POWER CAGE CLAMP connection, a locking tab holds the clamping point open. This way, the user has both hands free in order to position the wire end properly.

An additional patchboard level is established between the field and automation level. 8-level patchboard terminals of the 727 Series have replaced the previous soldering strips here. The patchboard terminals facilitate rewiring and measuring of individual signals. As neutral transfer points, they increase the flexibility of the system. The allocation of the signal lines can be quickly determined via the labels on the terminal blocks.

Text: Renate Klebe-Klingemann, WAGO

Photo: VW Kraftwerk, WAGO